Create Your First Project

Start adding your projects to your portfolio. Click on "Manage Projects" to get started

Spring 2025 - Applied Data Analysis - Defect Analysis & Process Improvement

Project type

Presentation

Date

Spring 2025

🏭 Defect Analysis & Process Improvement – Manufacturing in Tijuana

Course: Applied Data Analysis (DAT-475)

Term: Spring 2025

Tools Used: R, Tableau, One-Way ANOVA, Tukey’s HSD, Pareto Charts, Fishbone Diagram

Project Overview

In this project, I analyzed defect rates in electronic board production at a Tijuana-based manufacturing facility. The organization faced rising rework costs, production inefficiencies, and compliance risks related to IPC-A-610E standards — prompting the need for a data-driven approach to identify root causes and reduce manufacturing defects across multiple product models.

Objectives:

Pinpoint defect types contributing most to rework and cost

Compare defect rates across three product models using statistical testing

Identify root causes and recommend practical solutions to improve quality and efficiency

Methods & Tools:

Pareto Analysis (80/20 Rule): Revealed that 4–5 defect types (e.g., solder bridging, lifted components) were responsible for the majority of quality issues

One-Way ANOVA & Tukey’s HSD Test: Statistically confirmed that Model 1 had significantly higher defect rates than Models 2 and 3, guiding focus toward model-specific process evaluation

Tableau Dashboard: Visualized defect rates by model and category to support stakeholder communication and pattern discovery

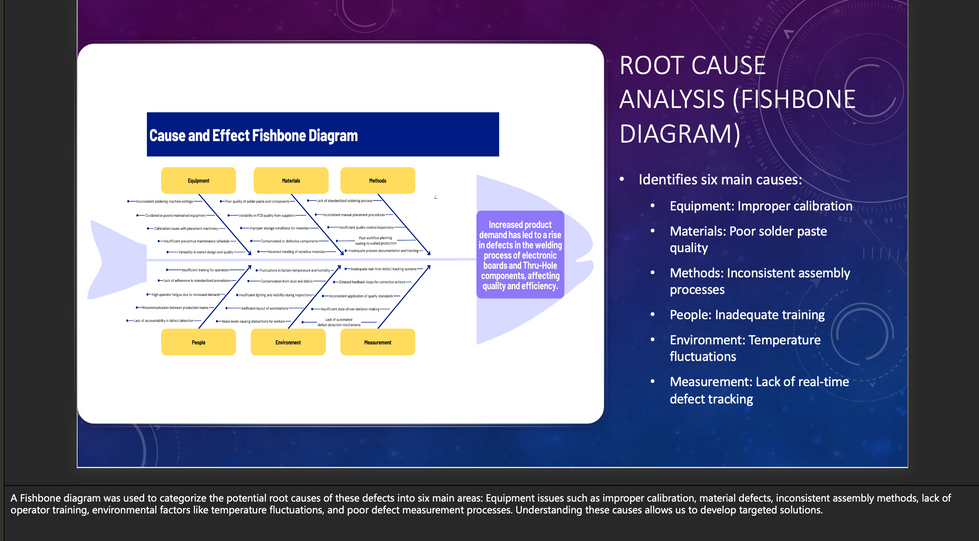

Fishbone Diagram: Conducted a root cause analysis across six dimensions: equipment, materials, methods, people, environment, and measurement

Key Findings:

Solder bridging and excessive solder were the most recurring and costly defects

Model 1 had significantly higher defect rates — likely due to inconsistent assembly processes and lack of operator training

Environmental and procedural inconsistencies played a role in quality variability across models

Recommendations:

Optimize soldering parameters and implement real-time defect detection systems

Improve operator training and enforce stricter quality control on component handling

Standardize successful practices from Models 2 and 3 and apply them to Model 1

Reflection:

This project taught me how to combine statistical rigor with operational insight. I learned how to use data to drive process improvement and communicate technical findings in a way that supports real change. It sharpened my ability to bridge analytics and strategy — a skill I carry forward into every project where data meets decision-making.